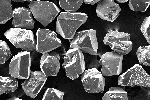

- Coated CBN

-

- Green Abrasive Inc. provide coated processing to most types of diamond and CBN superabrasives, the coating materials include Nickel, Copper, Titatium, Spickel nickel with difference percentage to enhance the grinding efficiency, bond retention, working thermal dissipation. The coated diamond and CBN abrasives can dramatically increase the tools working life.

- The coated processing to diamond and CBN micron powder are also available.

SignBond SystemType

SignBond SystemTypeVit Vitrified M Metal CBN3230T R Resin CBN3115N, CBN3210N El Electroplated

-

CBN 3115N R - Nickel 60% level coated to CBN3115, to improve the retention between CBN grit and resin bond, to reduce the heat on surface of the working component. It is strongly recommended for resin bond tools making.

- 60% Nickel based coating.

Size Available(Mesh) 60/80 80/100 100/120 120/140 140/170 170/200 200/230 230/325 325/400 400/500

CBN 3210N R - Using a special chemical coating method of 60% Nickel coating to CBN3210, can clearly improve the grinding efficiency and tools working life.

- 60% Nickel based coating.

Size Available(Mesh) 60/80 80/100 100/120 120/140 140/170 170/200 200/230 230/325 325/400 400/500

CBN3230T M - Titanium surface treated to CBN3230, improve the productivity of CBN metal bond tools, continuously form new working layers, prolong the metal bond tools’ working life.

- Titanium surface treatment.

Size Available(Mesh) 60/80 80/100 100/120 120/140 140/170 170/200 200/230 230/325 325/400 400/500