- Diamond Micron Powder

-

- Diamond micron powders are designed from the most tight particle size distribution premium grade, standard grade to economy grade. The grit shape is from blocky, semi-blocky to irregular shape to perform different strength and working efficiency, they can make the working surface have a prefect smooth surface and bring the satisfied grinding efficiency. It is suitable for processing natural diamond, gem stone, glass, ceramic, and PCD.

SignBond SystemType

SignBond SystemTypeVit Vitrified DMH, DMZ, DRS M Metal DMH, DMZ, LMD R Resin DMH, DMZ, LMD, DRS, DRE El Electroplated

-

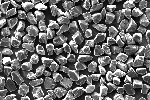

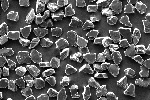

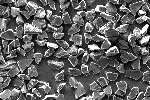

DMH Vit M R - Blocky shape with sharp edge, excenllent impact resistance, the most tightly controlled particle size distribution (PSD), and surface impurity, narrowest deviation, recommended for processing silica wafer and lapping of glass, ceramics.

- DMH N is 56% Ni-coated.

DMH N30 is 30% Ni-coated.

Size Available(Mesh) 0-0.125 0-0.25 0-1 0-2 0.5-1 1-2 1-3 2-3 2-4 3-5 3-6 4-8 5-7 5-9 5-10 6-12 7-12 8-16 10-14 10-20 12-22 14-20 15-25 20-25 - 20-28

20-30 20-40 22-36 30-40 40-60 40-50 36-54

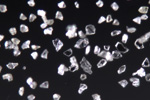

DMZ Vit M R - Blocky shape, high impact resistance, tightly controlled PSD, clean diamond surface. it is recommended for processing of glass, wafer, PCD lapping and polishing.

- DMZ N is 56% Ni-coatd.

DMZ N30 is 30% Ni-coated

Size Available(Mesh) - 0-0.25 0-1 0-2 0.5-1 1-2 1-3 2-3 2-4 3-5 3-6 4-8 5-7 5-9 5-10 6-12 7-12 8-16 10-14 10-20 12-22 14-20 15-25 20-25 - 20-28

20-30 20-40 22-36 30-40 40-60 40-50 36-54

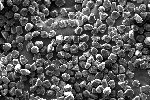

LMD M R - Blocky shape, well controlled size distribution, can meet most general finishing and lapping applications. It is a optimal selection when abrasive cost is a key fact of the tools.

Size Available(Mesh) - - - 0-2 0.5-1 1-2 1-3 2-3 2-4 3-5 3-6 4-8 5-7 5-9 5-10 6-12 7-12 8-16 10-14 10-20 12-22 14-20 15-25 20-25 - 20-28

20-30 20-40 22-36 30-40 40-60 40-50 36-54

DRS Vit R - Blocky shape, tightly controlled particle size distribution, clean diamond surface, higher toughness than GDMR10, the very good self-sharpness ability. It is recommended for polishing and lapping works to match the balance of high efficient removing rate and long working life.

- DRS N is 56% Ni-coated

DRS N30 is 30% Ni-coated

Size Available(Mesh) - - 0-1 0-2 0.5-1 1-2 1-3 2-3 2-4 3-5 3-6 4-8 5-7 5-9 5-10 6-12 7-12 8-16 10-14 10-20 12-22 14-20 15-25 20-25 - 20-28

20-30 20-40 22-36 30-40 40-60 40-50 36-54

DRE R - Irregular shape, well controlled particle size distribution, qualified clean diamond surface, matches all free surface polishing and finishing works when abrasive cost is a key aspect.

Size Available(Mesh) - - 0-1 0-2 0.5-1 1-2 1-3 2-3 2-4 3-5 3-6 4-8 5-7 5-9 5-10 6-12 7-12 8-16 10-14 10-20 12-22 14-20 15-25 20-25 - 20-28

20-30 20-40 22-36 30-40 40-60 40-50 36-54

- Blocky shape with sharp edge, excenllent impact resistance, the most tightly controlled particle size distribution (PSD), and surface impurity, narrowest deviation, recommended for processing silica wafer and lapping of glass, ceramics.